| |

|

|

Welcome to Vmeans Rubber Plastic Inc.

Specialisted Belting Supplies for Bulk Material Handling |

|

|

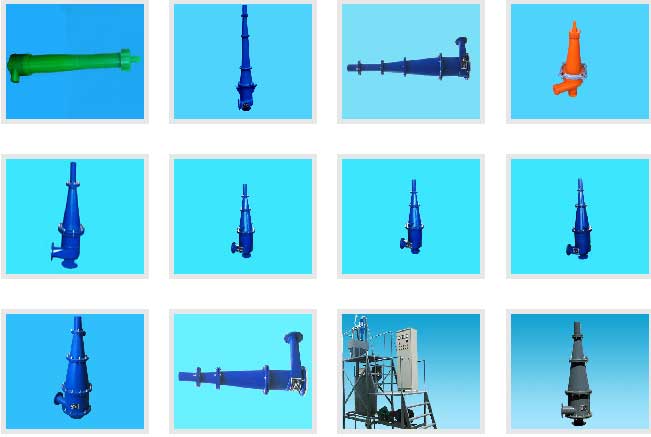

I. Metal Mine£ºHydraulic cyclone widely applied in mine-chosen technique in various metal mines. It mainly shows in the following works:

1. Classification for section I closed circuit grinding

2. Classification for section II closed circuit grinding

3. Regrinding for fine mine classification

4. Mud-removing before selection and after selection

5. Dam and backfill for gangue. |

|

|

¡¡¡¡In closed circuit grinding system, it features high classification efficiency and fine overfall fineness under high mine concentration. Classification efficiency is higher for 5-10% than common screw grader. It benefits for enhancing grader utilizing coefficient.

Choose proper specification and mode of cyclone according to grinding processing capacity, overfall fineness and sedimentation concentration. This is precondition of getting the most optimized work condition. Tongge Company is able to offer stand-alone, parallel connection machine or machine series in such specs as ¦µ50, ¦µ75, ¦µ100, ¦µ125, ¦µ150, ¦µ200, ¦µ250, ¦µ300, ¦µ350, ¦µ500 and ¦µ660.

Fine sand, less than 37¦Ìm, in gangue can not be used as dam materials during selecting mine. After the classification by cyclone, coarse granule left in the bottom of dam, fine granule move to the tail of gangue. Fine granule graded naturally during the movement. There is section full of clean water, which can be used for calling back of water. In the process of filling tail, we utilize cyclone for grading and concentrating to separate coarse granule so that to reduce load of filtering machine and to reach at the best effect. Use cyclone to finish dam and filling work so that to solve problems such as leaking mine, sink and overproof water discharged. So it can receive obvious economic and social benefit.

| |

| II. Wet Method of Desulfuration for Smoke and Gas for Heat-Engine Plant |

¡¡ |

|

Limestone Classification Cyclone

We always use closed circuit grinding system composed by cyclone and ball mill in preparation system of limestone. Generally, we usually use medium and small specification, cyclone with small cone angle, overfall fineness of cyclone can reach at -325 ¡Ý90%

Cyclone for Grading Gesso

Fit for concentrating gesso and reduce pressure in following procedure for vacuum belt spin-drier; choose small cone angle, small diameter of cyclone. Separated granularity is 10~44¦Ìm; quality concentration at the bottom of cyclone is 40~55%; adopt PU, NM wearable materials in cyclone, which features good wearable capacity and long life time.

Cyclone for Grading Sulfur and Ammonia

Choose cyclone with corresponded specification according to technique, separation granularity 50~100¦Ìm; concentration multiplying power of bottom flow is 3~4 times; adopt PU, NM wearable material in cyclone, good wearable performance, long lifetime.

|

|

| III. Sand and Mud Separator for Oil Field |

¡¡ |

Utilize cyclone for separating sand and mud during petroleum drilling work to purify slurry. Use¦µ250£¨10¡ä¡ä£©, ¦µ300£¨12¡ä¡ä£©cyclone for removing more than +45¦Ìm of rock debris, use ¦µ100£¨4¡ä¡ä£©, ¦µ125£¨5¡ä¡ä£©cyclone to eliminate more than +15¦Ìm of rock debris, use¦µ50£¨2¡ä¡ä£© cyclone for getting rid of +10¦Ìm rock debris.

Hydraulic cyclone manufactured by PU elastomer features in wearable, anti-aging, light and so on. Fit for outdoor work. Feature in efficient grading and small classification granularity for its special structure. |

|

|

IV. Wash and Select of Coal

|

¡¡ |

Cyclone without Pressure for Feeding but With Heavy Medium

Structure Characteristics:

There are three exits for discharging. Separate eligible fine coal, medium coal and recrement from single concentration of suspension.

High precision, wide range of granularity selection, adapt broad range.

Picked material and suspension enter into cyclone separately, save electricity consumption, reduce recrement and secondary coal capacity. Fit for reasonable arrangement of technique process.

Simple structure, without moving components; adopt high aluminum porcelain for separating manufacturing; features in good wearable performance and long lifetime.

Fit for selecting high sulfur, original coal which is hard to pick. |

|

| Technical Specifications of 3WZX Series Cyclone without Pressure for Feeding but with Heavy Medium |

| Type |

500/

350 |

600/

400 |

710/

500 |

850/

600 |

1000/

710 |

1100/

780 |

1200/

850 |

1300/

920 |

1400/

1000 |

| Inner Diameter of Section I Canister/mm |

500 |

600 |

710 |

850 |

1000 |

1100 |

1200 |

1300 |

1400 |

| Inner Diameter of Section II Canister/mm |

350 |

400 |

500 |

600 |

710 |

780 |

850 |

920 |

1000 |

| Angle of Section II Cone |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

| Feeding Pressure/MPa |

0.06~

0.08 |

0.07~

0.10 |

0.08~

0.11 |

0.10~

0.14 |

0.12~

0.19 |

0.14~

0.23 |

0.17~

0.29 |

0.19~

0.33 |

0.21~

0.38 |

| Feeding Granularity/mm |

¡Ü40 |

¡Ü45 |

¡Ü50 |

¡Ü60 |

¡Ü75 |

¡Ü80 |

¡Ü85 |

¡Ü95 |

¡Ü100 |

| Medium Circulating Volume/m3¡¤h-1 |

130~150 |

150~250 |

250~350 |

350~500 |

500~700 |

700~900 |

800~1200 |

1200~1500 |

1500~1800 |

| Processing Capacity/t¡¤h-1 |

30~50 |

50~80 |

70~120 |

110~170 |

160~230 |

220~300 |

300~400 |

350~450 |

450~550 | |

| Cyclone with Pressure Two-Product Heavy Medium |

¡¡ |

Structure Characteristics:

High upper limit for picking, efficient, high precision, quantity efficiency

more than 90%, deviation might less than 0.03Simple structure, without

moving components; adopt high aluminum porcelain for separating

manufacturing; features in good wearable performance and long lifetime.

Fit for selecting high sulfur, original coal which is hard to pick.

¡¡ |

|

| ¡¡ |

| Technical Specification of Cyclone with Pressure Two-Product Heavy Medium |

| Type |

350 |

500 |

600 |

710 |

850 |

1000 |

1100 |

1200 |

1300 |

1400 |

| Inner Diameter of Canister/mm |

350 |

500 |

600 |

710 |

850 |

1000 |

1100 |

1200 |

1300 |

1400 |

| Angle of Cone |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

| Feeding Pressure/MPa |

0.035~

0.1 |

0.05~

0.1 |

0.06~

0.1 |

0.06~

0.1 |

0.06~

0.1 |

0.1~

0.2 |

0.12~

0.25 |

0.12~

0.35 |

0.12~

0.35 |

0.12~

0.35 |

| Feeding Granularity/mm |

¡Ü10 |

¡Ü25 |

¡Ü40 |

¡Ü50 |

¡Ü60 |

¡Ü80 |

¡Ü95 |

¡Ü110 |

¡Ü120 |

¡Ü130 |

| Medium Circulating Volume/m3¡¤h-1 |

100

~

150 |

135

~

190 |

180

~

250 |

270

~

380 |

540

~7

50 |

630

~

880 |

650

~

900 |

675

~

945 |

900

~

1250 |

1150

~

1650 |

| Processing Capacity /t¡¤h-1 |

26

~

36 |

53

~

74 |

76

~

108 |

106

~

150 |

153

~

215 |

210

~

295 |

280

~

395 |

305

~

425 |

385

~

540 |

445

~

625 |

Cyclone Series > Hydraulic Cyclone Spec and Technical Parameters

|

Specif

ication |

Canister Interior Diameter

mm |

Cone Angle

£ï

|

Overfall Pipe Dia

mm

|

Bottom Exit Dia

mm

|

Max.

Perm

itted Fee

ding

Granu

larity

mm |

Feeding Pressure

Mpa

|

Processing Capacity

m3/h |

Classi

fication

Granu

larity

um

|

Overall Siz |

Mach

ine

Weig

ht

Kg

|

|

L

mm

|

W

mm |

H

mm |

|

FX660 |

660 |

20 |

180~240 |

80~150 |

16 |

0.03-0.2 |

250~350 |

74-220 |

1250 |

890 |

2650 |

995 |

|

FX500 |

500 |

20 |

130~200 |

35~100 |

10 |

0.03~0.3 |

140~220 |

74~200 |

850 |

790 |

2050 |

495 |

|

15 |

74~150 |

850 |

790 |

2380 |

540 |

|

FX350 |

350 |

20 |

80~120 |

30~70 |

6 |

0.04~0.3 |

60~100 |

50~150 |

775 |

605 |

1765 |

182 |

|

15 |

50~120 |

775 |

605 |

2115 |

230 |

|

FX300 |

300 |

20 |

65~115 |

20~50 |

5 |

0.04~0.3 |

45~85 |

50~150 |

665 |

585 |

1310 |

108 |

|

15 |

40~100 |

665 |

585 |

1505 |

169 |

|

FX250 |

250 |

20 |

60~100 |

16~45 |

3 |

0.06~0.35 |

40~60 |

40~100 |

540 |

480 |

1180 |

72 |

|

15 |

40~100 |

540 |

480 |

1220 |

77 |

|

10 |

30~100 |

540 |

480 |

1380 |

83 |

|

FX200 |

200 |

20 |

40~65 |

16~32 |

2 |

0.06~0.35 |

25~40 |

40~100 |

435 |

360 |

1050 |

60 |

|

15 |

30~100 |

435 |

360 |

1115 |

64 |

|

10 |

30~100 |

435 |

360 |

1205 |

69 |

|

FX150 |

150 |

20 |

30~45 |

8~22 |

1.5 |

0.06~0.35 |

11~20 |

30~74 |

280 |

295 |

690 |

20 |

|

15 |

30~74 |

280 |

295 |

900 |

22 |

|

8 |

30~74 |

280 |

295 |

1270 |

60 |

|

FX125 |

125 |

17 |

25~40 |

8~18 |

1 |

0.06~0.35 |

8~15 |

20~100 |

210 |

185 |

620 |

10 |

|

8 |

20~74 |

250 |

240 |

985 |

12 |

|

FX100 |

100 |

20 |

20~40 |

8~18 |

1 |

0.06~0.35 |

5~12 |

20~100 |

260 |

210 |

525 |

8 |

|

15 |

20~100 |

268 |

215 |

720 |

13 |

|

8 |

20~100 |

268 |

215 |

1000 |

21 |

|

FX75 |

75 |

15 |

15~22 |

6~12 |

0.6 |

0.1~0.4 |

2~5 |

20~74 |

240 |

230 |

465 |

4.2 |

|

6 |

5~40 |

240 |

230 |

800 |

7 |

|

FX50 |

50 |

15 |

11~16 |

3~8 |

0.3 |

0.1~0.4 |

1~2 |

10~74 |

160 |

155 |

350 |

2 |

|

6 |

5~30 |

160 |

155 |

590 |

2.5 |

Note: Design and manufacture according to customers¡¯ requirements.

Adopt PU, steel hull lining PU, steel hull lining TG-NM wearable material, steel hull lining high Aluminum porcelain in cyclone. |

Cone Sand Remover Utilize

separation principle of hydraulic cyclone, good removing effect; utilize polyether polyurethane in cone to enhance hydrolytic endurance; inner spiral structure to improve the effect for removing residue.

|

|

|